FAQ

What is an induction sterilizer and why use it for mushroom cultivation?

An induction sterilizer uses an electromagnetic field to heat the metal portion of your tool to sterilizing temperatures in a controlled way. You get consistent, repeatable sterilization without open flame, soot, or burning alcohol. This keeps your workflow cleaner and safer around alcohol wipes, 70 percent spray, and filtered air. It also frees up your hands so you can focus on sterile technique instead of fighting with a torch.

How does the induction sterilizer actually sterilize my tools?

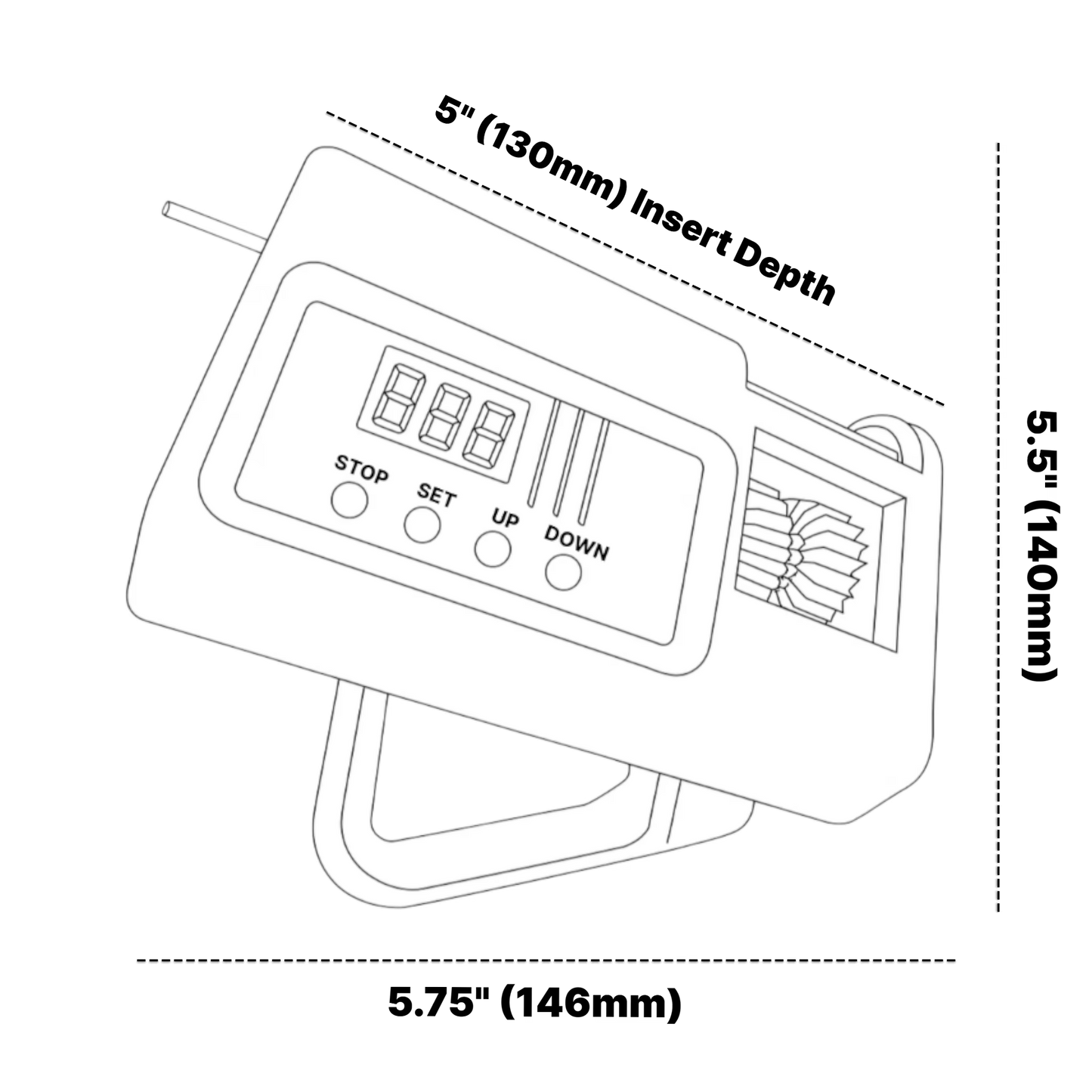

You insert the metal portion of your tool into the heating zone and the induction coil rapidly heats only that metal. The tip reaches red-hot sterilizing temperatures within a set cycle, then begins to cool while staying in the housing. You remove the tool once it has cooled to a usable temperature and go straight back to work. The electronics manage power and timing for you so you get the same result every cycle.

Which tools are compatible with the induction sterilizer?

The unit works best with magnetic stainless steel tools such as scalpels, forceps, tweezers, and inoculation tools designed for mycology. Non-metal or low-metal tools will not heat properly because induction relies on the metal itself to generate heat. Avoid plastic handles or parts inside the heating zone unless they are rated for high temperatures. Always check your specific model’s compatibility notes before using a new tool.

Is this safer than using an open flame or alcohol lamp in the lab?

Yes. You remove open flame from the equation, which lowers the risk when you work around isopropyl alcohol, paper towels, and plastic bags. The heating element is enclosed, and the tool only heats when it is in position and the cycle is running. That reduces accidental burns, flare-ups, and hot tools rolling around your workspace. It is still a high-temperature device, so you should follow the safety guidelines and let tools cool before use.

How do I use and maintain the induction sterilizer for best results?

Set the unit on a stable, ventilated surface, plug it into the correct power source, and follow the startup steps in the manual. Run a test cycle with a tool so you understand how hot it gets and how long it takes to cool to a working temperature in your environment. Keep the tool housing free of debris and wipe the exterior down regularly to prevent dust and spore buildup. Do not spray liquid directly into the housing and avoid blocking any vents so the electronics can stay cool and reliable over long sessions.