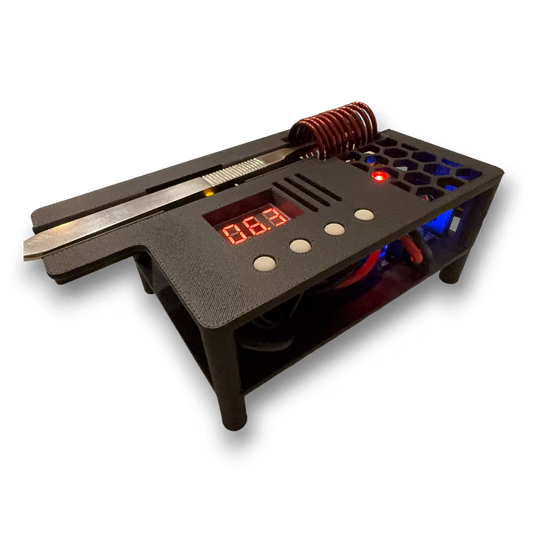

Hands free sterile workflow for mycology. Place your instrument in or on the sterilizer and it runs automatically for a timed cycle. It also acts as a safe parking place for the tool between uses so you can free up both hands during continuous work.

Ships pre programmed to 7.5 seconds, which is ideal for a common scalpel setup like a #11 blade on a #3 handle. Timing is user adjustable.